بیمهCone bottom silos

The principles of Tajhizavaran Company include a ten-year warranty for silos, a three-year warranty for all equipment and machinery, and a warranty for replacement of machinery and regular checks (to monitor the operation of machinery)...

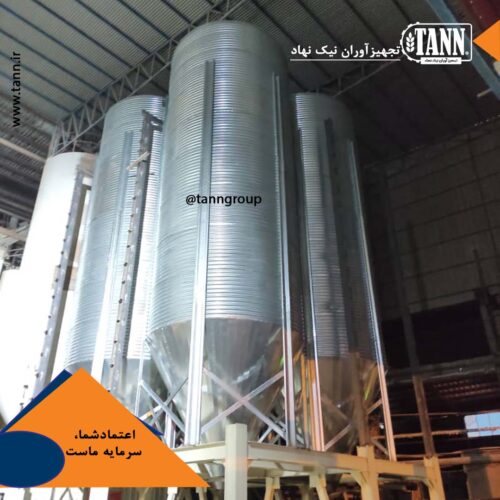

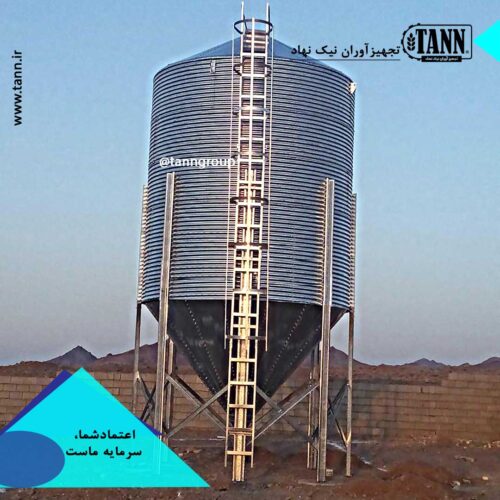

Cone bottom silos

For the fast and convenient drainage and saving time and energy

This type of silos can store all types of grains, including wheat, corn, soybeans, barley, pellets, maash, rice, legumes, and all granular materials.One of the major advantages of using cone bottom silos is the discharge of grains based on the order of loading time, which does not require stock taking.

From 5

cubic meters

the difference between flat bottom silos and hopper bottom ones is in the presence of its discharge hopper

From 1000

cubic meters

sheets are galvanized and type of sheets in the form of bolts and shutters

The services of the silos for Tajhizavaran

Custom-made raw materials

choosing raw materials suitable for the pressure & environmental conditions of each project

A three-year warranty

the warranty of generative machinery due to the use of qualified raw materials

Periodic services

Regular inspection of devices and parts after the end of the warranty period

Read before ordering Cone bottom silos

The sheets and raw materials used in the silos are galvanized, bolted, and shuttered.Structural calculations in the design and structure of silos are taken from the standards ANSI_ASAE EP 4332033, EUROCODE EN 1991, as well as wind speed km / hr145, ceiling pressure (fixed ceiling weight + snow pressure) 150 kg / m2, the density of stored products and more calculations.Customers' demands by providing a different range of dimensions and specifications are from 5 cubic meters to 1000 cubic meters. The slope of the hopper is determined by the flow of the product inside the silo. And it can be changed to a variety of 45 degrees to 60 degrees slopes. The quality of the sheets is galvanized.The variety of storable products can be increased by choosing different cone angles.An angle of 45 degrees is used for draining wheat, barleycorn, etc., and a hopper of 60 degrees is used for more oily products, such as soybeans.