Chain Conveyor

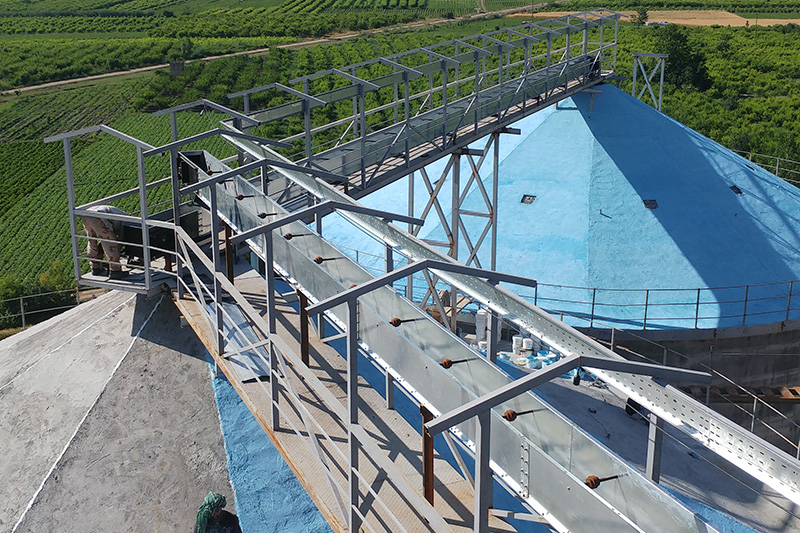

They are used for loading and draining grains in silos horizontally with a slope

Chain conveyors are part of the transportation equipment that is used to load and drain the grain in the silo horizontally and with a slope.The minimum economic transfer capacity of products without damaging the product is 20 tons per hour, and the maximum is 250 tons per hour.

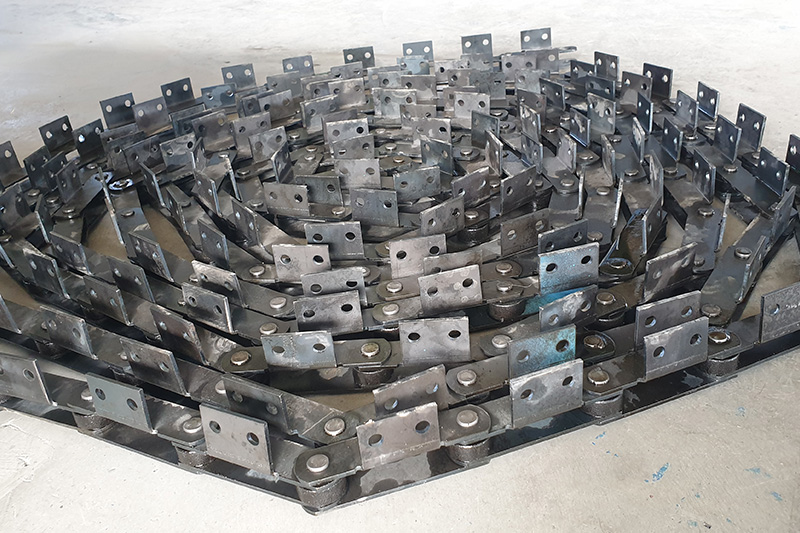

The sheets are made of galvanized steel and bolted and are divided into three parts of top, bottom, and body.The top and bottom parts of the device are prepared and assembled, and they are sent after quality-control tests and verification of the needed power to spend the least time during installation.The structure is completely bolted, which makes it easy to install. This product is professionally designed and produced based on the length and capacity, depending on the demand of the type of project, the diameter, and volume of the silo, and the customer’s needs.All conveyor chains are produced exclusively with three different types of chains in pitches 75, 100, and 125, which are produced by the Tajhizavaran group, and prefabricated chains are never used in any project.

• The sheets are fully galvanized and bolted

• Bushings and pins are made of steel and solidified

• The ceiling sheet has a slope to prevent rain

• Wear resistant Teflon is used on chain fins

• The sprocket is made of 45-ck steel and solidified

• Use of ball bearing and high-consumption bearings (easy access to the relevant ball bearing in the city)

• Assessment valves allow inspection in the necessary conditions and facilitate maintenance